Let’s cut to the chase. Building your synthetic turf is a big deal. Whether you’re transitioning from a natural grass field or updating at replacement time, you need accurate measurements of existing conditions for pre-construction design & planning. 3D laser scanning technology captures exact measurements of the field’s planarity, allowing our team to create a plan that eliminates change orders and ensures your new field meets industry standards. We’ll cover how this technology takes your field to the next level, providing a safe and playable field for your athletes.

What is 3D Laser Scanning?

3D laser scanning technology uses advanced cameras to capture millions of data points per second and provides precise measurements down to ½.” When we stitch the scans together, our team of experts can deliver data in a point cloud or building information model (BIM) that allows you to explore a real-time representation of your project. These services remove guesswork and design confusion, giving you confidence in every decision.

3D laser scanners in architecture have become standard practice when extremely precise measurements are needed. Sportworks Field Design’s sister company, TrueScan, scans warehouse floors, performing a precise floor flatness analysis when an exact grade is needed. Sportworks is applying this technique to fields, tracks, tennis courts, and stadiums.

How Do We Use 3D Laser Scanning for Sports Facilities?

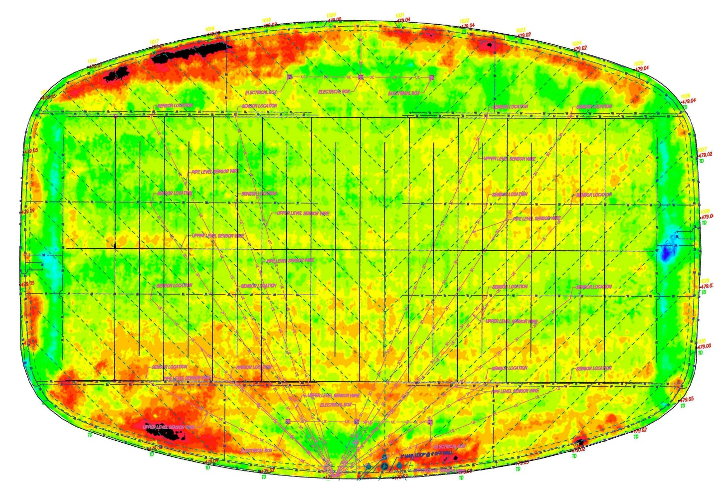

After completing the scans, we’ll compare the 3D laser scanning data to the ideal field surface grade by producing a heat map that shows all the discrepancies. You’ll see if your field has high or low spots and where the field differs from the ideal plan. By comparing the new scan data to old plans and drawings, Sportworks can determine potential causes of discrepancies and suggest ways to fix any problems before digging.

Combining 3D laser scanning data with Sportworks testing and assessment services provides a comprehensive and holistic analysis, helping you make well-educated decisions on what remediations to spend your money on.

What are Some Benefits of Using 3D Laser Scanning?

3D laser scanning allows measurements to be collected in a compressed timeframe while your team still has access to the field. As-built data is so accurate that Sportworks can provide exact calculations of how much material is needed to fix the issues, giving you the precise number of cubic yards needed before you tear up your existing turf. Additionally, 3D scanning allows us to deliver an accurate analysis of the finished field after the synthetic turf is replaced and provides you with assurance of a high-quality finished product.

Our dedicated team of land surveyors, civil engineers, landscape architects, and 3D laser scanning professionals takes designing and planning your sports facility project to the next level. If you have questions about using 3D laser scanning on your next project, contact Sportworks today. [vc_custom_heading text=”Other News” use_theme_fonts=”yes”][sth_featuredPosts arrow_style=”style-3″ featured_posts=”29, 217, 349″]

Leave a comment